-

Shape Control in Hot Rolled Strip Production

In the production of strip steel, only by ensuring its good shape can production proceed smoothly and product output and quality be continuously improved. When the residual stress inside the strip steel is large enough, it will cause the strip steel to warp, manifested as side bending, edge waves...Read more -

Steel Mills Safety Regulations for Raw Materials and Scrap

1. Loose material 1.1 The storage method shall be determined according to the characteristics and safety requirements of the loose materials in the furnace; Furnace materials should be kept dry. 1.2 When rail transportation is adopted, the distance between the outside of...Read more -

How will China’s Steel Develop in the Context of Low-carbon Transition

The iron and steel industry is an important basic industry of the national economy, an important support for building a modern country, and an important field to achieve green and low-carbon development. China's steel industry carbon emissions account for about 18% of the overall manufacturing ca...Read more -

The Latest Ranking of World’s Major Steel-producing Countries (Regions) in 2022

On February 2, worldsteel announced the latest ranking of the world's 40 major steel-producing countries (regions) in 2022, with China ranking first with 1.013 billion tons of crude steel production (down 2.1% year-on-year), India (124.7 million tons, up 5.5% year-on-year) ranked second, Japan (8...Read more -

Difference between Induction Furnace and EAF

Item Induction Furnace EAF Picture Applicable Range of Raw Materials Refining capacity of induction furnace is limited, the process flexibility is small, and the quality requirements of smelting raw materials are relatively high. The applicable smelting raw materials are usually: ...Read more -

Analysis on the Causes of Steel Breakout of Continuous Casting Billets

Breakout in continuous casting is a serious production accident in continuous casting. From billet continuous casting, the breakout phenomenon can be divided into: corner crack breakout, middle breakout, pull breakout, and start breakout. From the analysis of the reasons of continuous casting br...Read more -

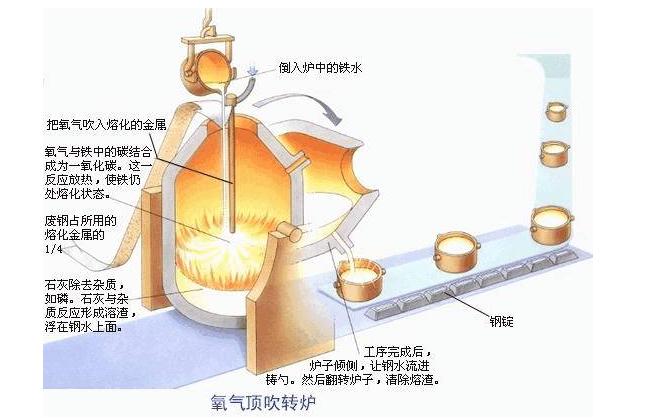

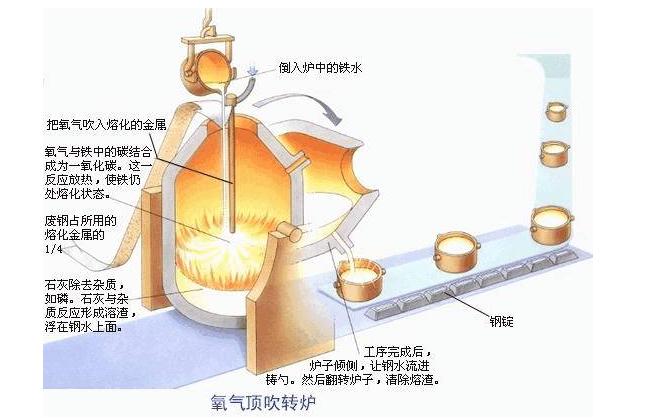

Basic Principles and Methods of Steelmaking

Steelmaking first makes iron. Steel comes from pig iron. Pig iron obtained by smelting iron ore has a high carbon content and contains many impurities (such as silicon, manganese, phosphorus, sulfur, etc.). Therefore, pig iron lacks plasticity and toughness, has poor mechanical properties, and ca...Read more -

Continuous Casting Powder

1.What is the function of continuous casting mold flux? During the casting process, powder or granular slag, called mold slag, should be continuously added to the molten steel surface of the mold. The role of the protective slag has the following aspects: (1)Thermal insulation to prevent heat dis...Read more -

Countermeasures for Blast Furnace Tuyere Burning Loss

According to the analysis of the damage form of blast furnace tuyere, formulate a targeted blast furnace operation management system, and technical measures to prevent tuyere burning and leakage, improve the service life of the tuyere, reduce the air break rate, improve economic benefits, and ach...Read more -

Reasons for Blast Furnace Tuyere Burning Loss

1.Furnace Condition is Unstable and the Hearth is Piled Up Such a situation is often encountered in production. The blast furnace condition has been fluctuating greatly, the stability is very poor, and the air is frequently added and subtracted, and the long-term stability of the blast furnace ca...Read more -

Industrial Wastewater Treatment Technology in Steel Enterprises

The industrial sewage treatment system mainly includes several major treatment units: primary sedimentation tank, adjustment tank, chemical reaction tank, microfiltration tank, and membrane treatment system. The main function of the primary sedimentation adjustment tank is to adjust the quantity...Read more -

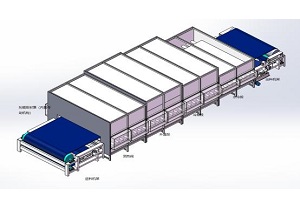

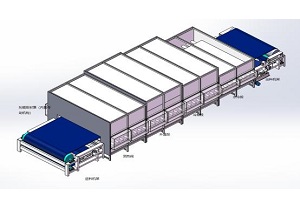

Large Muffleless Belt H2 Reduction Furnace and Process

1. Large Muffleless Belt H2 Reduction Furnace The heat-resistant steel mesh belt drive and the synchronous self-rotating roller drive are combined to form a coupled drive, and combined with the muffle-free H2 reduction furnace body to implement wide-band surface, long-di...Read more

- 0086-13599895807

- 0086-13808561119

- 86-594-6975200

- phyllis@rerollingmillccm.com

- CCM&ROLLING MILLS ONE STOP TURNKEY SERVICE SUPPLIER