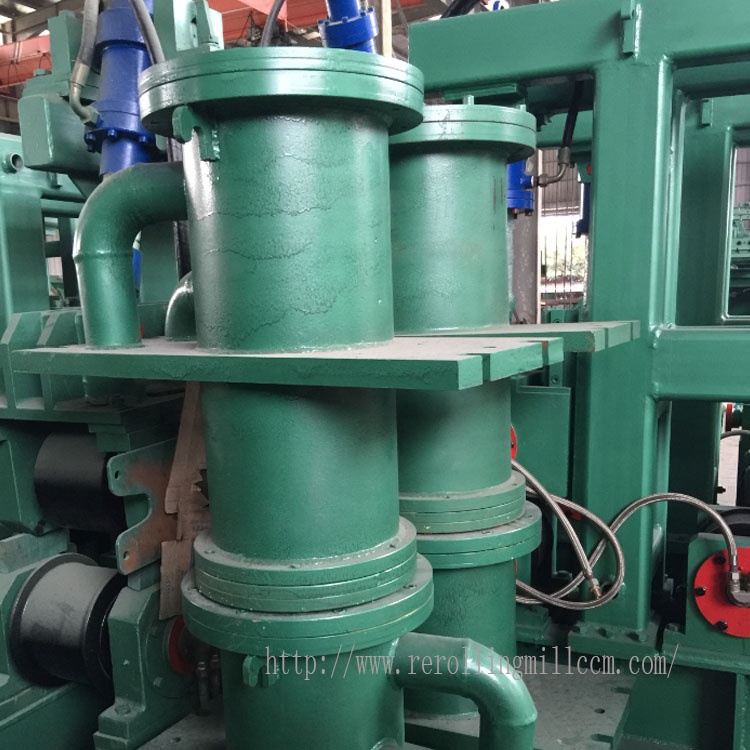

China Factory for Ccm Casting Machine - Metal Mold Copper Crystallizer for Continuous Casting Machine Cooling Crystallizer -Geili Detail:

- Condition:

-

New

- Warranty:

-

1 Year

- Place of Origin:

-

Fujian, China

- Brand Name:

-

GEILI

- Voltage:

-

220V/380V/415V/440V

- Weight:

-

Customized

- Certification:

-

ISO 9001:2015

- Dimension(L*W*H):

-

Customized

- Power(W):

-

Customized

- Name:

-

Crystallizer

- Capacity:

-

As Per Customer

- Mold Size:

-

60mmx60mm-150mmx150mm

- After-sales Service Provided:

-

Engineers available to service machinery overseas

Product Description

Continuous casting crystallizer is a tank container and it is used to complete the initial solidification of liquid steel and formation of casting billets. It can ensure the cross sectional dimensions and enough shell thickness of casting billets. This equipment uses the structure of copper pipe. The upper end of pipe is sealed by the cap at the top. And the lower end uses the way of side seal. The casting crystallizer is equipped with stainless steel water jacket cover that is durable and sturdy. It can be mounted at the upper part of vibration device and main operating platform. Our product can be also placed on the magnetic stirrer to improve the performance of casting billets and obtain better billets. In addition, a measurement device is available. Therefore, through this container, we can continuously monitor the molten steel level.

Main Features

1) Simple structure, easy in installation and maintenance.

2) Excellent design

3) Efficient production capacity

4) Running in a high automatic production

5) Unique style and pattern

Company Information

FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD

was founded in 1995,formerly known as Xianyou Rolling Mill Manufacturer.In 2001,merged with Xianyou Bangtou Mill Roll Manufacturer. In 2008,we focused on continuous casting and rolling production line equipment. In 2011,the company reorganized and established FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD ,which engaged in metallurgical equipment,mainly in steel-making,continuous casting and complete rolling production line research and development,design,manufacturing, installation and general contracting services.

Main products: all kinds of specifications continuous casting machines, rolling production line equipment and various auxiliary equipment, also the spare parts. Besides, we provide technical consultant, turnkey solution and one-stop service for steel plant of deformed rebar , wire rod , angle bar, channel beam, strip and other steel related production line. The Solution was based on the customer request, such as annual capacity from 30,000 tons to over 800,000 tons, rolling speed from 3 m/s to 90 m/s.

Company Exhibition

Our Service

1)Offering proposal with best solution and reasonable price for production line as per customers' invest and capacity requirement

2)Providing turn-key service of site planning, machinery designing, manufacturing, installation and commissioning for the full

production lines to meet customers requirement.

3)Technical support. We will arrange engineers on site to install and debug the production lines until the final products are meet to customers' require

4)Perfect after-sales with long-term technical support, such as after-sales adjust the production line, develop new products or improve the equipment

Product detail pictures:

Related Product Guide:

Cooperation

With state-of-the-art technologies and facilities, strict good quality regulate, reasonable cost, exceptional assistance and close co-operation with prospects, we're devoted to supplying the top benefit for our customers for China Factory for Ccm Casting Machine - Metal Mold Copper Crystallizer for Continuous Casting Machine Cooling Crystallizer -Geili, The product will supply to all over the world, such as: Tanzania , Indonesia , Eindhoven , The best and original quality for spare parts is a most important factor for transportation. We may stick on supplying original and good quality parts even a little profit earned. God will bless us to do kindness business forever.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!

-

Chinese wholesale 4 High Rolling Mill - Steel ...

View Detail -

Hot-selling Steel Re Rolling Mill - Rolling Mi...

View Detail -

Special Price for Ccm Casting Machine - High Q...

View Detail -

Factory Supply U-Beam – Construction C Ch...

View Detail -

China Cheap price Billet Casting Machine - Fou...

View Detail -

2020 wholesale price 3 Roll Mill - New type &...

View Detail