China wholesale Cooling System For Rebar - CNC Walking Beam Cooling Bed Electric Conveyor Table for Bar -Geili Detail:

- Place of Origin:

-

Fujian, China

- Brand Name:

-

GEILI MACHINERY

- Bar type:

-

Rebar, Round, Square , etc....

- product size:

-

3mm ~ 36mm / 4 X4 mm - 16 X 16 mm

- Certification:

-

ISO9001:2008

- Dimension:

-

Customize

- Type:

-

Fully Automatic

- Usage:

-

Base For the Cooling Bed

- Application:

-

Steel

- Color:

-

Customzied

- Material:

-

Steel Material

- Function:

-

Conveyor

- After-sales Service Provided:

-

Engineers available to service machinery overseas

Product Description

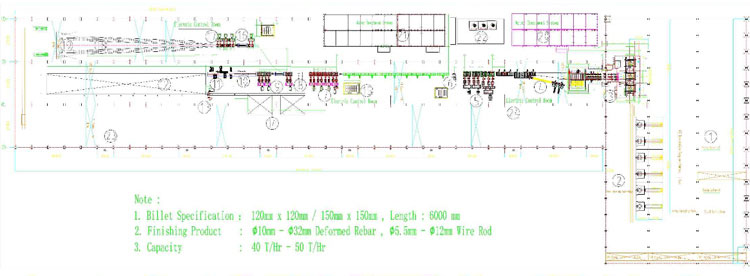

CNC Walking Beam Cooling Bed Electric Conveyor Table for Bar

Cooling bed is an important equipment in the field of steel rolling. It used to receiving, transmissing and cooling the rolled piece. After sizing or reducing , the temperature of pipe is generally above 700 °C. It must be cooled to below 150 °C for subsequent finishing process. The pipe cooling is usually carried out on cooling bed.

Main partsCooling bed include mechanical drive system, water cooling system, work surface and fixed support and so on.Advantage(1) simple structure;(2) low investment;(3) easy operation.

Composition:Cooling bed consist of mechanical transmission system, water cooling system, cooling bed working table and fixed support.

Working principle: The finished products are delivered to cooling bed via conveying roller table, and then extracted by the rack step by step, being pushed to the top of cooling bed, to achieve the effect of cooling rolled piece.

Main application: The cooling bed equipment is mainly used for naturally slow on-line cooling of rolled steel plate. In the profile production line, cooling bed also has the function of preventing bending, to prevent irregular curve of profiles through the process of natural cooling due to various quality problems. Areas of application: mainly used in steel industry, metallurgical industry, rebar production line, round production line, pipe production line, etc.

Company Information

FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD

Main products: all kinds of specifications continuous casting machines, rolling production line equipment and various auxiliary equipment, also the spare parts. Besides, we provide technical consultant, turnkey solution and one-stop service for steel plant of deformed rebar , wire rod , angle bar, channel beam, strip and other steel related production line. The Solution was based on the customer request, such as annual capacity from 30,000 tons to over 800,000 tons, rolling speed from 3 m/s to 90 m/s.

Cambodia( CHINA STEEL Co, LTD )Project

View our Factory

1) Providing professional proposal of suitable production line as per customers' invest and capacity requirement2) Providing turn-key service of designing, manufacturing, installation and commissioning for the whole production lines to meet customers requirement3) Providing foundation layout and arrangement diagram for your plant4) Providing technical support. We will send various technical staff to the site until the final products are meet to customers' own request.5) Good after-sales service will be provided. Our long-term technical service will be provided if you want to adjust the production line, develop new products or improve the equipment.6) Quality warranty will be promised.

Quality Control:Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performed service adheres to a defined set of quality criteria or meets the requirements of the client or customer. Finish Product QCEnsure all the dimension and technical process are correctDrawing QCEnsure all the drawing are inspected by Profesional EnginnersShipping QCEnsure the product pass to customer are optimum and correct quantity.

Packing & Shipping

Product detail pictures:

Related Product Guide:

Cooperation

Just about every member from our large efficiency income crew values customers' wants and enterprise communication for China wholesale Cooling System For Rebar - CNC Walking Beam Cooling Bed Electric Conveyor Table for Bar -Geili, The product will supply to all over the world, such as: Mozambique , San Francisco , venezuela , We have established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we are looking forward to even greater cooperation with overseas customers based on mutual benefits. Please feel free to contact us for more details.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.

-

PriceList for Small Induction Furnace For Sale ...

View Detail -

Good Quality Section Steel – Hot Rolled S...

View Detail -

Good Quality Section Steel – Corrugated R...

View Detail -

Good Quality Deformend Steel Bar – Low Pr...

View Detail -

Good Quality Flat Bar – China Suppliers H...

View Detail -

Good Quality Flat Bar – Spring Steel Galv...

View Detail