China wholesale Medium Frequency Induction Furnace - Electric Steelmaking Furnace Industrial Heat Treatment EAF -Geili Detail:

- Condition:

-

New

- Warranty:

-

1 Year

- Place of Origin:

-

Fujian, China

- Brand Name:

-

GEILI

- Usage:

-

Melting Furnace, Steel Casting

- Voltage:

-

6KV - 35KV

- Certification:

-

ISO 9001:2015

- Type:

-

Arc Furnace

- Dimension(L*W*H):

-

Customized

- Specification:

-

Low energy consumption

- Application:

-

Melting Furnace

- Feature:

-

High Efficiency

- Furnace Type:

-

Induction Melting Electric Furnace

- Function:

-

Power

- Price:

-

Normal

- Color:

-

Customzied

- Technology:

-

Advanced

- Delivery Time:

-

30 Days

- After-sales Service Provided:

-

Field installation, commissioning and training

- Power(W):

-

50KW - 5000KW

- Weight:

-

Customized

Product Description

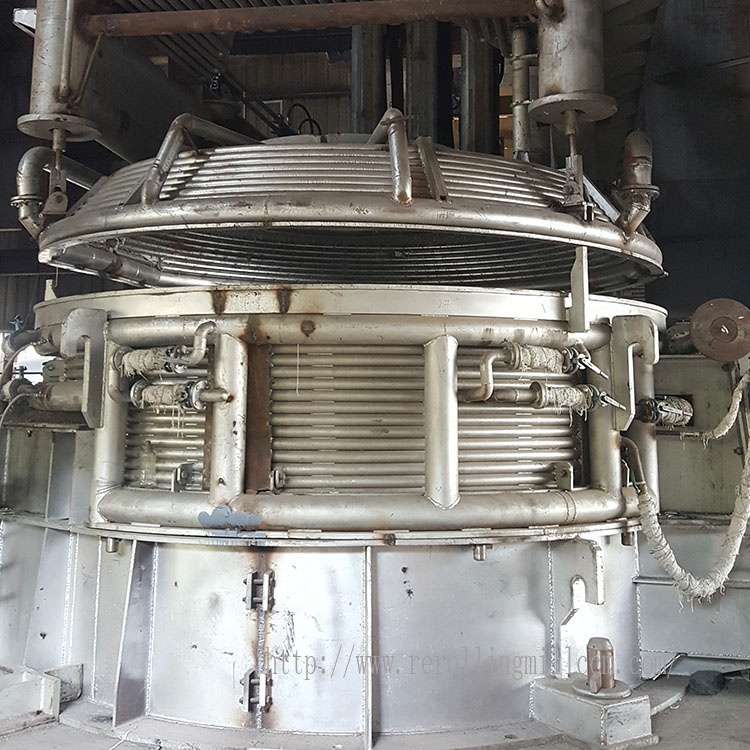

Smelting Furnace Constitution

1. Furnace body

2. Medium frequency power supply cabinet

3. Water cooling cable

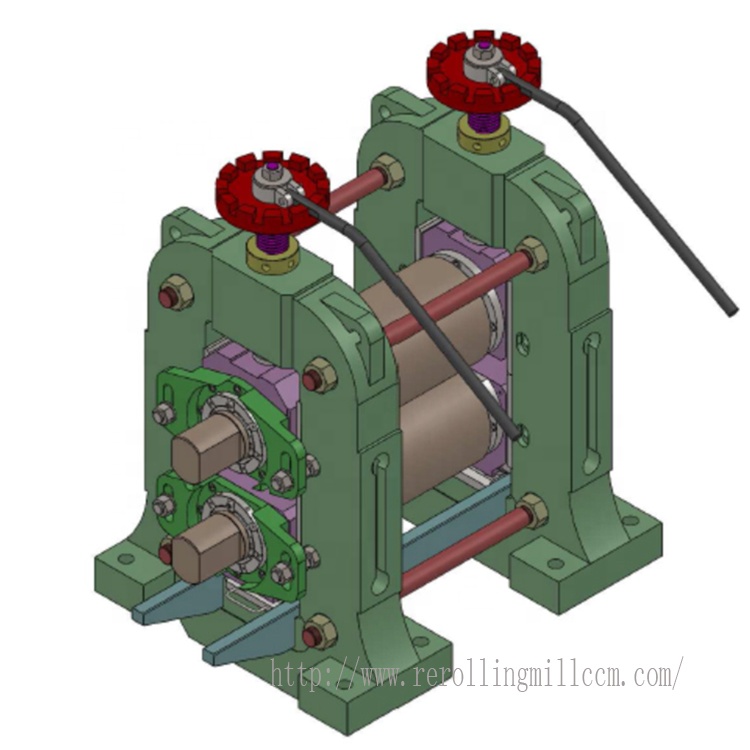

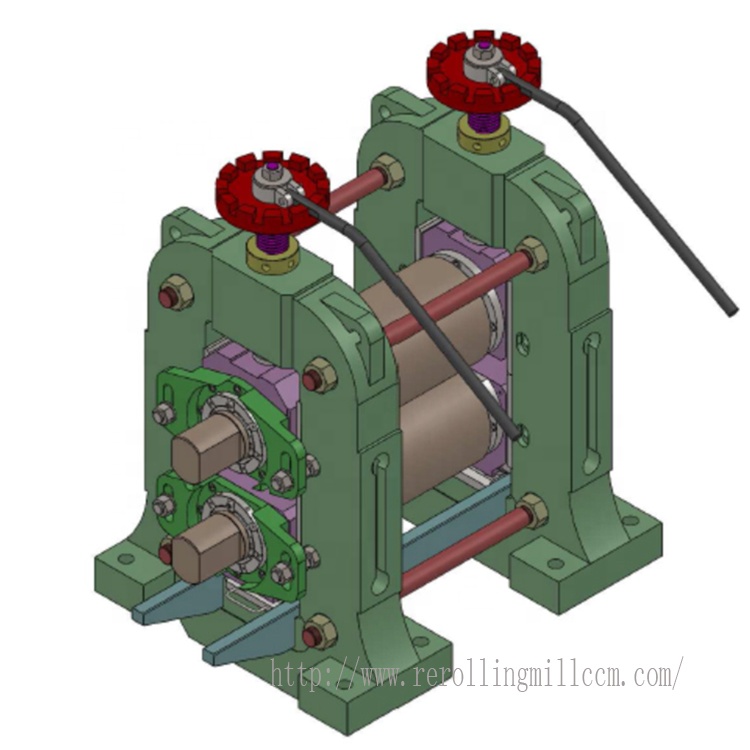

4. Reduction machine

5. Crucible mold

6. Compensation capacitor rack.

7. Chiller

8.Transformer

9. Installation drawings and specifications

Features

| 1) Fast smelting with low production cost |

| 2) low-pollution and environment-friendly |

| 3) A direct effect from the cold furnace melting. |

| 4) Power adjustment flexibility. |

Applications

EAF arc for a heat source to scrap as raw material for steel smelting general, high-quality carbon steel, alloy

steel of various equipment for smelting. Its structure for the furnace cover Rotary Open Top feeding, torque

motor electrodes automatic adjustment movements, large cross-section of water-cooled cables, furnace and

the furnace cover upgrading Tilting rotation using hydraulic, electrical control by PLC control, technology advanced.

Company Information

FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD

was founded in 1995,formerly known as Xianyou Rolling Mill Manufacturer.In 2001,merged with Xianyou Bangtou Mill Roll Manufacturer. In 2008,we focused on continuous casting and rolling production line equipment. In 2011,the company reorganized and established FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD ,which engaged in metallurgical equipment,mainly in steel-making,continuous casting and complete rolling production line research and development,design,manufacturing, installation and general contracting services.

Main products: all kinds of specifications continuous casting machines, rolling production line equipment and various auxiliary equipment, also the spare parts. Besides, we provide technical consultant, turnkey solution and one-stop service for steel plant of deformed rebar , wire rod , angle bar, channel beam, strip and other steel related production line. The Solution was based on the customer request, such as annual capacity from 30,000 tons to over 800,000 tons, rolling speed from 3 m/s to 90 m/s.

Quality Control:

Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performed

service adheres to a defined set of quality criteria or meets the requirements of the client or customer.

Finish Product QC

Ensure all the dimension and technical process are correct

Drawing QC

Ensure all the drawing are inspected by Profesional Enginners

Shipping QC

Ensure the product pass to customer are optimum and correct quantity.

Packing & Shipping

Product detail pictures:

Related Product Guide:

Cooperation

Using a complete scientific top quality management program, great high-quality and fantastic religion, we win great track record and occupied this area for China wholesale Medium Frequency Induction Furnace - Electric Steelmaking Furnace Industrial Heat Treatment EAF -Geili, The product will supply to all over the world, such as: Lithuania , Guinea , Amsterdam , we sincerely hope to establish a good and long-term business relationship with your esteemed company through this opportunity, based on equality, mutual benefit and win-win business from now to the future. "Your satisfaction is our happiness".

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!

-

2020 wholesale price Slab Casting Machine - S...

View Detail -

Hot-selling Steel Re Rolling Mill - Metallurgy...

View Detail -

Reasonable price Induction Melting Furnace Pric...

View Detail -

Hot-selling U-Channel - Hot Rolled U Beam Sect...

View Detail -

2020 China New Design Cold Mill - Roll Forming...

View Detail -

Good Quality Hr Round Bar – Suitable Pric...

View Detail