Chinese Professional Hot Rolling Mill Production Line - Steel Plant Production Line For TMT Bar / Deformed Rebar with Annual Output of TON -Geili Detail:

- Place of Origin:

-

Fujian, China

- Brand Name:

-

GEILI MACHIENRY

- Model Number:

-

TR 8000

- Application:

-

Building Construction

- Diameter:

-

6mm - 35 mm

- Length:

-

12m

- Standard:

-

AISI, ASTM, BS, DIN, GB, JIS

- Grade:

-

Other

- Product name:

-

Deformed Steel Bar

- Technique:

-

Latest advance technology

- Material:

-

Steel

- Technology:

-

Arc Rigid

- Shape:

-

Round, Square, Rectangle

- Main Application:

-

Buliding Construction

- Feature:

-

Easily Assembled

- Certification:

-

ISO 9001:2015

- Warranty:

-

1 Year

- Delivery Time:

-

30 Days

Product Description

Continuous casting is a new energy-saving technique to casting the molten steel to a section shape or a certain size billet continuously and continuous casting machine is the equipment to complete this process. It includes pouring equipment, major equipment, cutting area equipment, dummy bar collection and transmission equipment. We supply the whole production lines, from induction furnace, CCM to rolling mills, cooling bed and packing.

Company Information

FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD

was founded in 1995,formerly known as Xianyou Rolling Mill Manufacturer.In 2001,merged with Xianyou Bangtou Mill Roll Manufacturer. In 2008,we focused on continuous casting and rolling production line equipment. In 2011,the company reorganized and established FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD ,which engaged in metallurgical equipment,mainly in steel-making,continuous casting and complete rolling production line research and development,design,manufacturing, installation and general contracting services.

Main products: all kinds of specifications continuous casting machines, rolling production line equipment and various auxiliary equipment, also the spare parts. Besides, we provide technical consultant, turnkey solution and one-stop service for steel plant of deformed rebar , wire rod , angle bar, channel beam, strip and other steel related production line. The Solution was based on the customer request, such as annual capacity from 30,000 tons to over 800,000 tons, rolling speed from 3 m/s to 90 m/s.

|

Customer Requirement |

Capacity, electricity, land, etc. |

|

Solution Discussion |

Technical and design discussion; Most suitable proposal. |

|

Initial Stage |

Provide plan layout diagram; Provide quotation machinery list. |

|

Detail Check & Confirm |

On-site inspection & verification; Both parties more details discussion. |

|

Contract Confirmation |

Final price, supply scope, terms & conditions etc. |

|

Payment |

Pay advance payment into the sellers's account; Issue original irrevovable L/C. |

|

Equipment Production |

Design and manufacture according to the supply list and equipment parameters in the contract. |

|

Shipping Transportation |

Delivery at the appointed time; Provide equipment shipping list and customer declaration data. |

|

Site Construction |

Equipment foundation; Supervision for the complete plant engineering; Installation. |

|

Equipment Commissioning |

Conduct cold commissioning and hot commissioning after installation.

|

| Final Acceptance | Buyer's final acceptance of equipment

Training provided by the supplier |

| Perfect Service |

24-hour after-sales service; Provide spare parts purchasing and matainance service technical support. |

Quality Control:

Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performed service adheres to a defined set of quality criteria or meets the requirements of the client or customer.

Finish Product QC

Ensure all the dimension and technical process are correct

Drawing QC

Ensure all the drawing are inspected by Profesional Enginners

Shipping QC

Ensure the product pass to customer are optimum and correct quantity.

Packing & Shipping

As a professional and experience manufacturer in China, we can supply designing, manufacturing, installation and commissioning of the equipment with "turn-key" service.

Please send us more information about your project, we would like to give you our proposal immediately after getting your details. Sincerely welcome you to come and visit our plant.

Product detail pictures:

Related Product Guide:

Cooperation

Our goods are commonly recognized and reliable by consumers and may satisfy continually developing economic and social needs for Chinese Professional Hot Rolling Mill Production Line - Steel Plant Production Line For TMT Bar / Deformed Rebar with Annual Output of TON -Geili, The product will supply to all over the world, such as: Iraq , French , Norwegian , we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we've gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.

-

Chinese wholesale Continuous Casting Machine Fo...

View Detail -

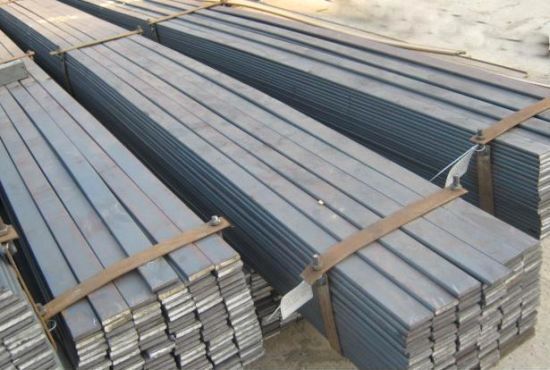

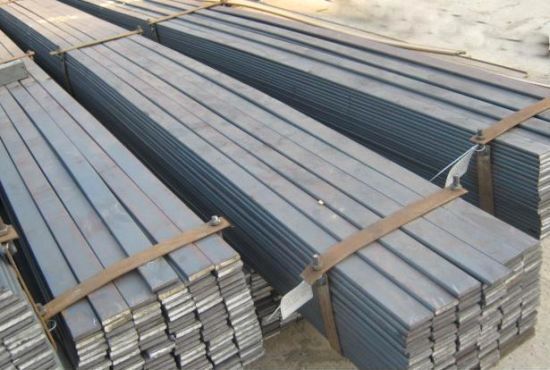

Good Quality Flat Bar – Mild Steel Price ...

View Detail -

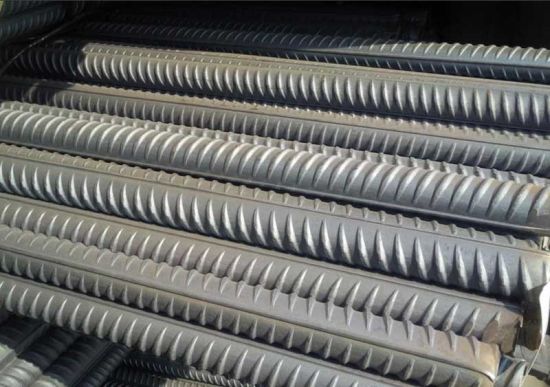

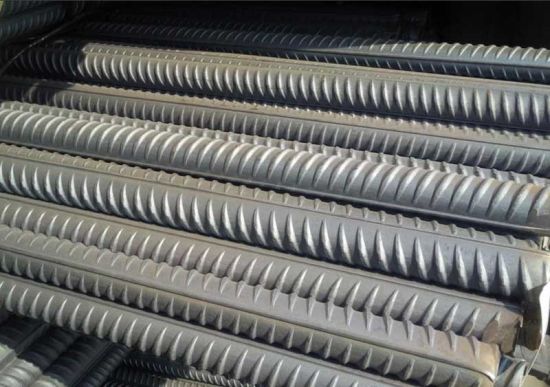

Good Quality Deformend Steel Bar – Hot Ro...

View Detail -

Chinese Professional Copper Rolling Mill - 3 R...

View Detail -

2020 High quality Ccm Casting - Metallurgy Equ...

View Detail -

Good Quality Section Steel – Universal Eq...

View Detail