Chinese wholesale Complete Steel Rolling Production Line - Deformed Bar Steel Plant Production Line for Rebar -Geili Detail:

- Place of Origin:

-

Fujian, China

- Brand Name:

-

GEILI

- Model Number:

-

W1030

- Application:

-

Industrial

- Diameter:

-

6mm-35mm

- Length:

-

12m

- Standard:

-

AISI, ASTM, BS, DIN, GB, JIS

- Grade:

-

Steel

- Product name:

-

Steel Plant Production Line for Rebar Deformed Bar

- Color:

-

Metal Color

- Warranty:

-

1 Year

- Delivery Time:

-

60 D

- Certificate:

-

ISO 9001:2015

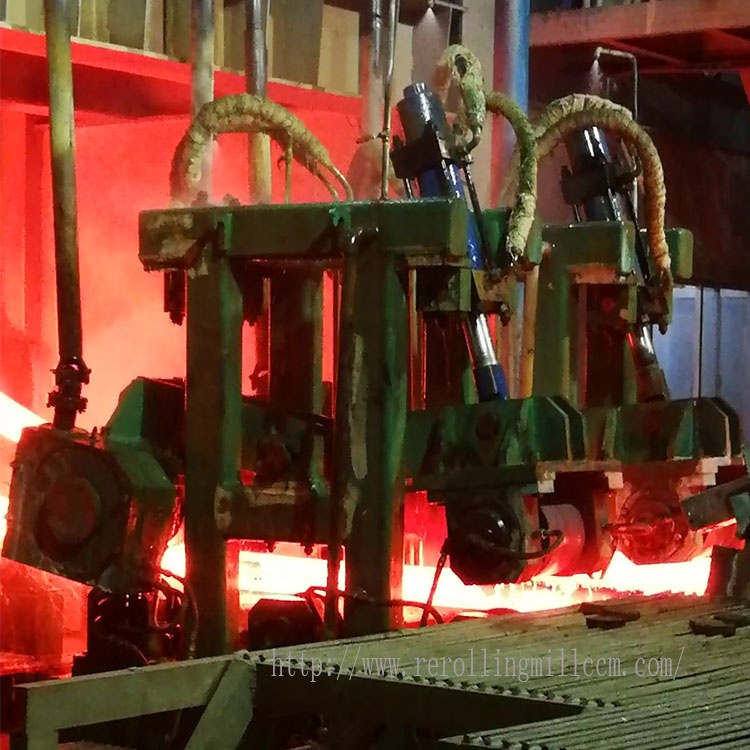

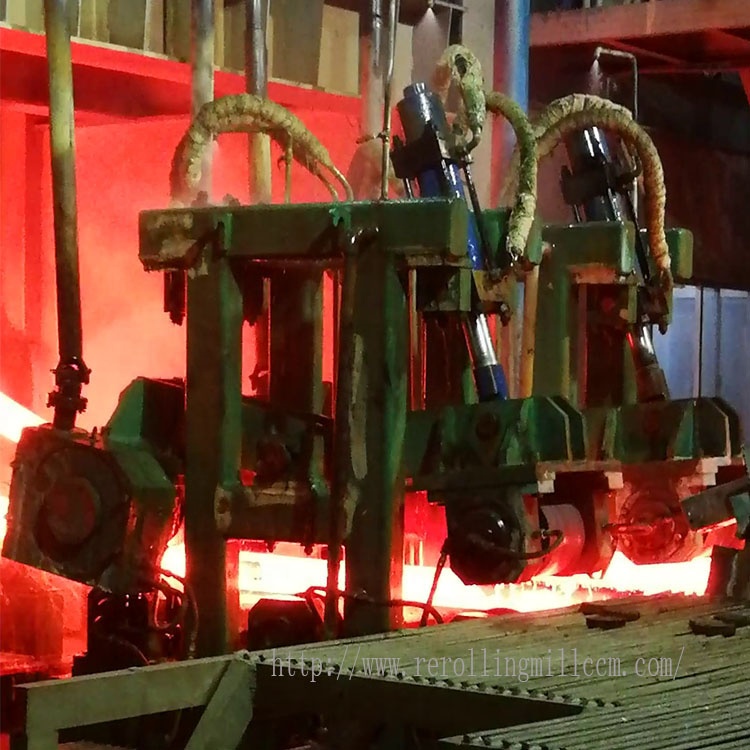

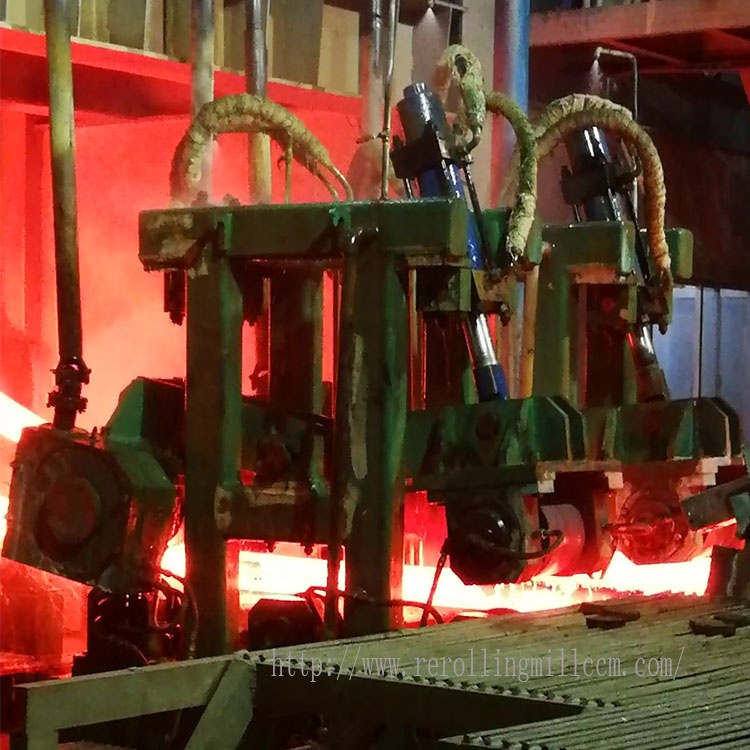

Product Description

Continuous casting is a new energy-saving technique to casting the molten steel to a section shape or a certain size billet continuously and continuous casting machine is the equipment to complete this process. It includes pouring equipment, major equipment, cutting area equipment, dummy bar collection and transmission equipment. We supply the whole production lines, from induction furnace, CCM to rolling mills, cooling bed and packing.

Technology Parameter

Production capacity: 50,000 MT - 800,000 MT/year

Type of steel: quality carbon steel, low alloy steel etc.

Material: billet size from 80mm x 80mm to 150mmX150mm

Final products: Φ5.5-Φ12mm wire rod, Φ8-Φ40mm rebar

Components

Mill stand

Roller

Roller bearing

Rack

Rail support

Roll adjusting device

Upper roll balancing device

Transmission device

Auxilliary equipment

Rolling Mill Process

Heating furnace------come out furnace/CCM------Rough Roll------Intermediate Roll------

Pre-finish Roll-------Finished Product-------Packing

Company Information

Main products: all kinds of specifications continuous casting machines, rolling production line equipment and various auxiliary equipment, also the spare parts. Besides, we provide technical consultant, turnkey solution and one-stop service for steel plant of deformed rebar , wire rod , angle bar, channel beam, strip and other steel related production line. The Solution was based on the customer request, such as annual capacity from 30,000 tons to over 800,000 tons, rolling speed from 3 m/s to 90 m/s.

Our Service

Pre-sales Service After-sales Service

Inquiry and consulting support. Training how to instal the machine, training how to use themachine

Quality Control:

Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performed service adheres to a defined set of quality criteria or meets the requirements of the client or customer.

Finish Product QC

Ensure all the dimension and technical process are correct

Drawing QC

Ensure all the drawing are inspected by Profesional Enginners

Shipping QC

Ensure the product pass to customer are optimum and correct quantity.

Packing & Shipping

As a professional and experience manufacturer in China, we can supply designing, manufacturing, installation and commissioning of the equipment with "turn-key" service.

Please send us more information about your project, we would like to give you our proposal immediately after getting your details. Sincerely welcome you to come and visit our plant.

<img src="/uploads/HTB1zvSEXyrxK1RkHFCcq6AQCVXaj.jpg" alt="Deformed Bar Steel Plant Production Line for Rebar" ori-width="750" ori-height="750

Product detail pictures:

Related Product Guide:

Cooperation

We have a professional, efficiency team to provide quality service for our customer. We always follow the tenet of customer-oriented, details-focused for Chinese wholesale Complete Steel Rolling Production Line - Deformed Bar Steel Plant Production Line for Rebar -Geili, The product will supply to all over the world, such as: Orlando , Uzbekistan , Bangalore , It using the world's leading system for reliable operation, a low failure rate, it suitable for Argentina customers choice. Our company is situated within the national civilized cities, the traffic is very convenient, unique geographical and economic conditions. We pursue a people-oriented, meticulous manufacturing, brainstorm, build brilliant" business philosophy. Strict quality management, perfect service, reasonable price in Argentina is our stand on the premise of competition. If necessary, welcome to contact us by our website or phone consultation, we'll be happy to serve you.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.

-

Good Quality Wire Rod Hot Rolling Mini Mill Mac...

View Detail -

2020 wholesale price 3 Roll Mill - GEILI MACH...

View Detail -

Good Quality Section Steel – Q235B Ss400 ...

View Detail -

High definition Steel Billet Plants - Consulta...

View Detail -

2020 High quality Roughing Roll Factory - Stee...

View Detail -

Good Quality Hr Round Bar – Sourcing Hot ...

View Detail