- Condition:

-

New

- Place of Origin:

-

Fujian, China

- Brand Name:

-

GEILI

- Voltage:

-

220V-380V-440V-660V

- Weight:

-

Customized

- Certification:

-

ISO9001, CE , SGS

- Type:

-

Hot Rolling Mill

- Dimension(L*W*H):

-

Customized

- Power(W):

-

22kw-1000kw

- Applicable Industries:

-

Manufacturing Plant

- Key Selling Points:

-

Automatic

- After Warranty Service:

-

Field maintenance and repair service

- Local Service Location:

-

Viet Nam, Philippines, Indonesia, Bangladesh

- Showroom Location:

-

Viet Nam, Philippines, Indonesia, Thailand, Bangladesh, Uzbekistan

- Product name:

-

Rebar Rolling Mill

- Final product:

-

Section Steel

- Raw material:

-

Continuous Casting Billets

- Application:

-

Steel Industry

- Output:

-

Section Bar

- Rolling type:

-

Hot Rolling Mill

- Usage:

-

Metal Rolling Equipment

- Delivery Time:

-

30 Days

- Warranty:

-

1 YEAR

Product Description

Rolling mill is a mill or factory where ingots of heated metal are passed between rollers to produce sheets or bars of a required cross section and form.

We supply the whole production lines, from induction furnace, CCM to rolling mills, cooling bed and packing. Our hot rolling mill can produce 8-32mm deformed rebar, round bar, also wire rod.

Technology Parameter:

| Production capacity | 50,000 MT - 800,000 MT/year |

| Type of steel | quality carbon steel, low alloy steel etc. |

| Material | billet size from 80mm x 80mm to 150mmX150mm |

| Final products | Φ5.5-Φ12mm wire rod, Φ8-Φ40mm rebar |

Components:

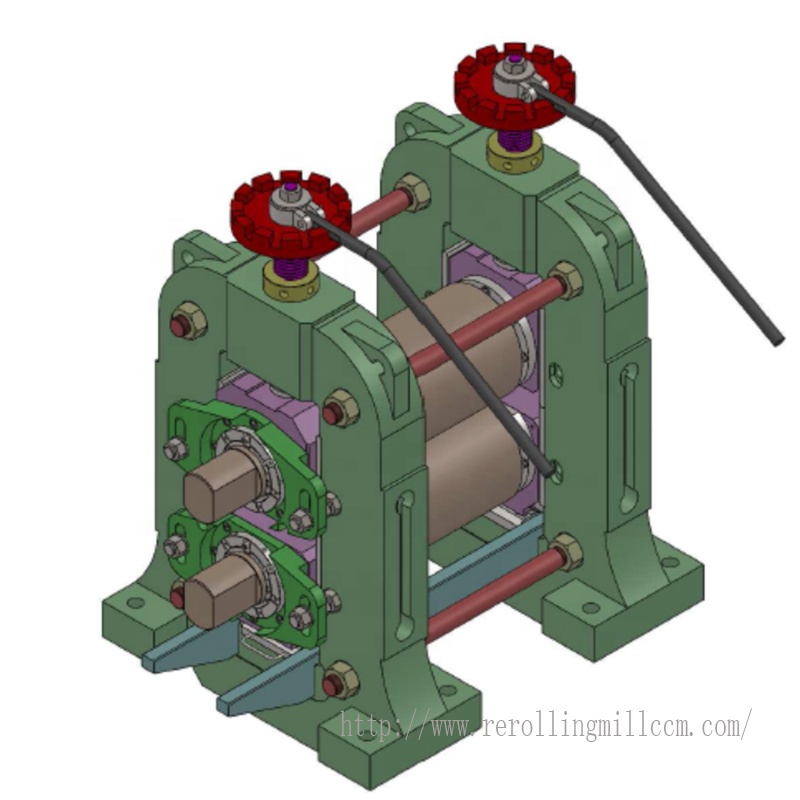

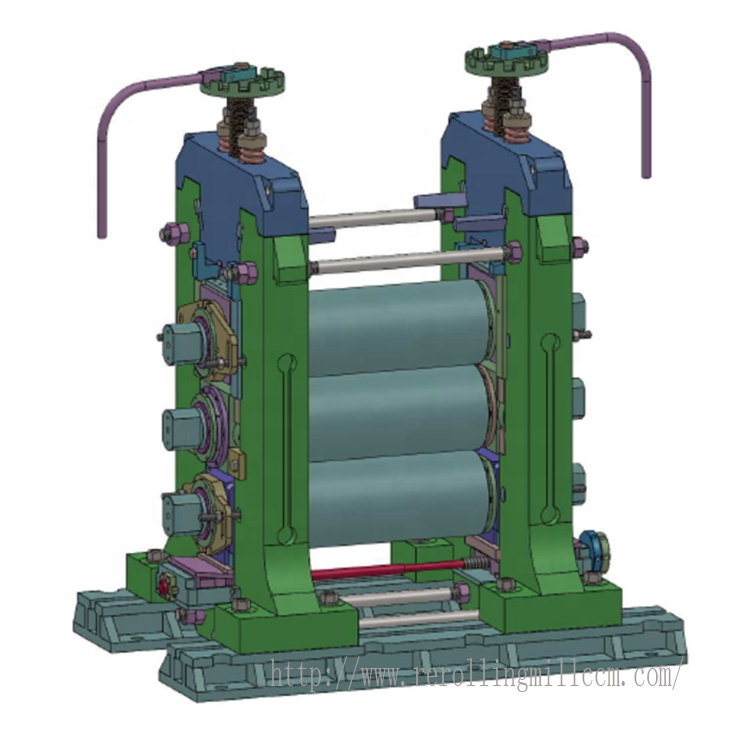

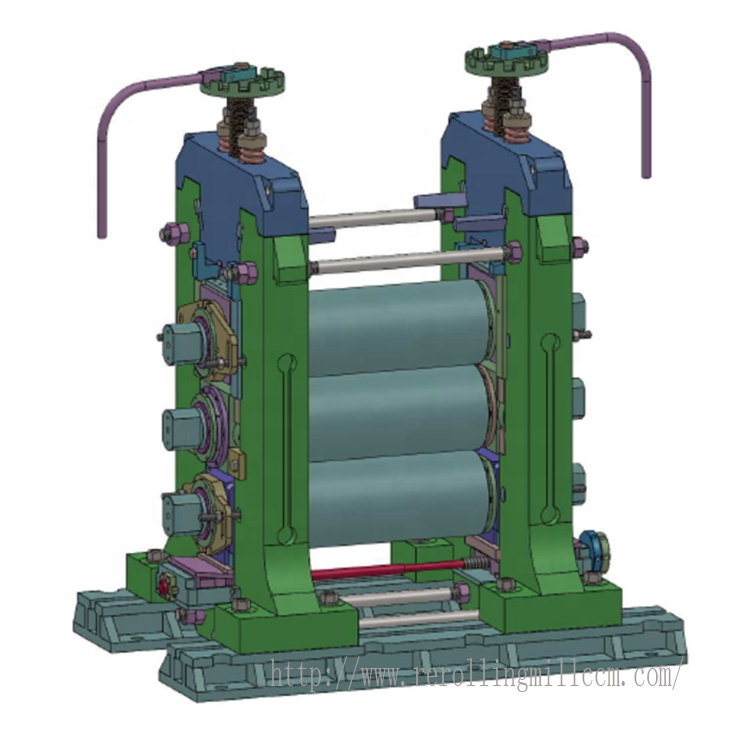

Mill stand

Roller

Roller bearing

Rack

Rail support

Roll adjusting device

Upper roll balancing device

Transmission device

Auxilliary equipment

Rolling Mill Process:

Heating furnace------come out furnace/CCM------Rough Roll------Intermediate Roll------

Pre-finish Roll-------Finished Product-------Packing

|

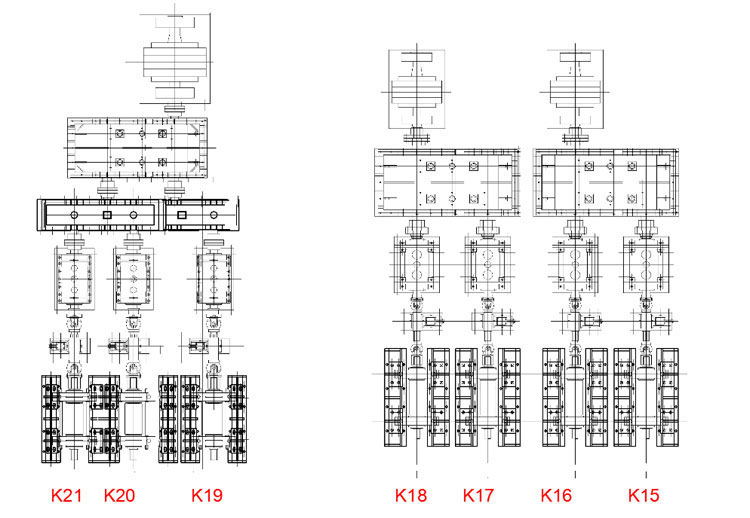

Stand |

Process |

Model |

Motor |

|

1 |

K21-K19 |

550 |

AC 1250KW |

|

2 |

K18-K17 |

450 |

AC 1250KW |

|

3 |

K16-K15 |

450 |

AC 1250KW |

|

4 |

K14-K13 |

365 |

DC 1250KW |

Company Information

FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD

was founded in 1995,formerly known as Xianyou Rolling Mill Manufacturer.In 2001,merged with Xianyou Bangtou Mill Roll Manufacturer. In 2008,we focused on continuous casting and rolling production line equipment. In 2011,the company reorganized and established FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD ,which engaged in metallurgical equipment,mainly in steel-making,continuous casting and complete rolling production line research and development,design,manufacturing, installation and general contracting services.

Main products: all kinds of specifications continuous casting machines, rolling production line equipment and various auxiliary equipment, also the spare parts. Besides, we provide technical consultant, turnkey solution and one-stop service for steel plant of deformed rebar , wire rod , angle bar, channel beam, strip and other steel related production line. The Solution was based on the customer request, such as annual capacity from 30,000 tons to over 800,000 tons, rolling speed from 3 m/s to 90 m/s.

Pre-sales Service After-sales Service

Inquiry and consulting support. Training how to instal the machine, training how to use themachine

1)Offering proposal with best solution and reasonable price for production line as per customers' invest and capacity requirement

2)Providing turn-key service of site planning, machinery designing, manufacturing, installation and commissioning for the full

production lines to meet customers requirement.

3)Technical support. We will arrange engineers on site to install and debug the production lines until the final products are meet to customers' require

4)Perfect after-sales with long-term technical support, such as after-sales adjust the production line, develop new products or improve the equipment

Quality Control

Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performed service adheres to a defined set of quality criteria or meets the requirements of the client or customer.

Finish Product QC

Ensure all the dimension and technical process are correct

Drawing QC

Ensure all the drawing are inspected by Profesional Enginners

Shipping QC

Ensure the product pass to customer are optimum and correct quantity.

Packing & Shipping

-

High Speed Automatic Steel Rolling Mill Wire Ro...

View Detail -

CNC Machine Metal Sheet Rebar Cutter for Steel ...

View Detail -

Steel Rebar Rolling Mill Manufacturers Wire Rod...

View Detail -

China CCM Small Continuous Casting Machine for ...

View Detail -

Rolling Mill Rolls High Speed Steel Embossing R...

View Detail -

Metal Wire Cutter Machine Electric Steel Flying...

View Detail