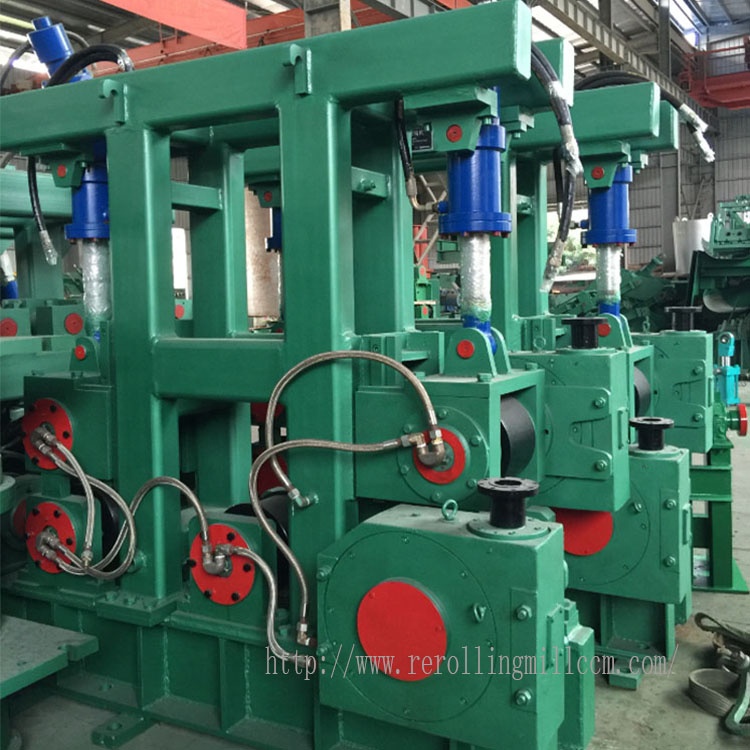

Good Quality Continuous Casting Machine - Automatic Pull Machine Steel Straightening for Rebar Straightener -Geili Detail:

- Condition:

-

New

- Warranty:

-

1Year

- Place of Origin:

-

Fujian, China

- Brand Name:

-

GEILI

- Voltage:

-

380V

- Weight:

-

7.3T

- Certification:

-

ISO9001:2015

- Type:

-

Straightener & Cutter

- Use:

-

Bar

- Dimension(L*W*H):

-

1500*500*1800mm

- Power(W):

-

100KW

- Product name:

-

Automatic Pull Machine Steel Straightening for Rebar Straightener

- Material:

-

Steel

- Application:

-

Steel

- Color:

-

Customized

- Usage:

-

Steel Bar Straightening Cutting

- Function:

-

Straigthen

- Technology:

-

Advanced

- Quality:

-

High Precision

- Price:

-

Normal

- Delivery Time:

-

60 Days

- After-sales Service Provided:

-

Field installation, commissioning and training

Product Description

Straightening machine is used on various continuous casting machine to straightening and leveling billet after secondary cooling. For different size of continuous casting machine, withdrawal and straightening machine has different kinds of shape, for R3m, R4m, R5.25m and for R6m.

It is mainly used in arc continuous casting machine. when billet goes along the dummy bar, it comes into the straightening machine, the shape of billet changes from arc to straight.The machine is very important in the whole set of equipment

Company Information

FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD was founded in 1995,formerly known as Xianyou Rolling Mill Manufacturer.In 2001,merged with Xianyou Bangtou Mill Roll Manufacturer. In 2008,we focused on continuous casting and rolling production line equipment. In 2011,the company reorganized and established FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD ,which engaged in metallurgical equipment,mainly in steel-making,continuous casting and complete rolling production line research and development,design,manufacturing, installation and general contracting services.

FAQ

Q : Are you trading company or manufacturer?

A: We are manufacturer.

Q:How long is your delivery time?

A:Generally it is 60 days, it is according to quantity requires.

Q:What is the term of payment?

A: Payment <=1000USD, 100% in advance. Payment >=1000USD, 30% T/T in advance, balance before shipment.

Q:Do you have any Oversea Project?

A: Yes, we have service over 20 countries for their Plant set up Project.

If you are interested in this equipment, please don't hesitate to contact us!

If the machine is not suitable for your plant, please e-mail us the following information::

1. What's the quality standard of billet do you want to casting? Is it common carbon steel or low carbon steel?

2. What's the billet size and length?

3. Do you have melting furnace? If yes, how many tons of furnace with how many quantity?

4. What's the capacity per hour?

According to your information, we will offer high efficiency design and best price for it.

Packing & Shipping

As a professional and experience manufacturer in China, we can supply designing, manufacturing, installation and commissioning of the equipment with "turn-key" service.

Please send us more information about your project, we would like to give you our proposal immediately after getting your details. Sincerely welcome you to come and visit our plant.

Product detail pictures:

Related Product Guide:

Cooperation

We've been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for Good Quality Continuous Casting Machine - Automatic Pull Machine Steel Straightening for Rebar Straightener -Geili, The product will supply to all over the world, such as: Portland , Lyon , Nairobi , Faced with the vitality of the global wave of economic integration, we've been confident with our high-quality items and sincerely service to all our customers and wish we can cooperate with you to create a brilliant future.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.

-

Good Quality Deformend Steel Bar – Deform...

View Detail -

Wholesale Price China Induction Furnace For Sal...

View Detail -

Wholesale Price Rebar Rolling Mill - Horizonta...

View Detail -

Factory Supply U-Beam – 2019 High Quality...

View Detail -

Good Quality Section Steel – Universal Ch...

View Detail -

2020 High quality Ccm Casting - Slab Continuou...

View Detail