High Performance Megatherm Furnace - Steel Scrap Induction Melting Casting Medium Frequency Induction Furnace -Geili Detail:

- Condition:

-

New

- Warranty:

-

1 Year

- Place of Origin:

-

Fujian, China

- Brand Name:

-

GEILI

- Usage:

-

Melting Furnace

- Voltage:

-

380V ~ 660V

- Certification:

-

ISO 9001 215

- Type:

- Dimension(L*W*H):

-

Customize

- Power (kW):

-

380

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant

- Application:

-

Melting Metal

- Product Name:

-

Induction Metal Melting Furnace

- Feature:

-

Energy-saving

- Function:

-

Power

- Technology:

-

Advanced

- Delivery Time:

-

30 Days

- Power(W):

-

50KW - 5000KW

- After-sales Service Provided:

-

Field installation, commissioning and training

- Weight:

-

Customize

Product Description

Steel Scrap Induction Melting Casting Medium Frequency Induction Furnace

The induction furnace is the device converting three phase power current into single phase intermediate frequency current and enabling metal to produce eddy current loss through electromagnetic field induction to achieve heating and melting and is applicable to melting, heating or holding of steel, copper, iron, aluminum, zinc, tin, nickel silver and other ferrous or nonferrous metal and alloy material as well as heating treatment prior to forging, sintering and tube-bending forming in casting and melting industries.

Performances and features

1) Using a zero-voltage scanning soft-start mode, in any case may at any time to start or stop, will not have impact on power supply.

2) Fast smelting with low production cost; low-pollution and environment-friendly;

3) A direct effect from the cold furnace melting. Dissolved material will be fully dumped clean. Molten material is easy to replace.

4) Power adjustment flexibility. Be able to continuously smooth adjustment. Temperature uniformity can be easily controlled. Oxidation burning is less.

5) Furnace shell using cast aluminum or steel structure, small footprint; furnace flip dump convenience, according to the need to use electric, manual, hydraulic tilting furnace and other means.

6) Designed to automatically adjust angle of inverter circuit that can automatically adjust the load impedance match, without adjustment of capacitance compensation and always run the equipment in good working condition; power supply system diagnostic error function, easy maintenance.

Furnace Usage

Melting Furnace Mainly used in melting steel, iron, copper, aluminum and alloy, is with high melting efficiency, good electricity saving effect, good metal component uniformity, less burning loss, speedy temperature rise, easy control of temperature, is suitable to all kinds of metal melting.

Smelting Furnace constitution

1. Furnace body

2. Medium frequency power supply cabinet

3. Water cooling cable

4. Reduction machine

5. Crucible mold

6. Compensation capacitor rack.

7. Chiller

8.Transformer

9. Installation drawings and specifications

Company Information

FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD

was founded in 1995,formerly known as Xianyou Rolling Mill Manufacturer.In 2001,merged with Xianyou Bangtou Mill Roll Manufacturer. In 2008,we focused on continuous casting and rolling production line equipment. In 2011,the company reorganized and established FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD ,which engaged in metallurgical equipment,mainly in steel-making,continuous casting and complete rolling production line research and development,design,manufacturing, installation and general contracting services.

Why Choose GEILI?

1. Expert R&D team and Professional service staff

2. Turn-Key service , Perfect after-sales service ,

3. OEM , Reliable Manufacturer

4. Competitive price , Optimum quality product

5. Machines easy operation, Steady performance, Low energy consumption

6. Lower investment , minimize maintenance

7. Products are customized for different requires

8. Adjustable production capability

9. On-time delivery

10. Warranty Period

Customer & Certificate

Services area

1)Offering proposal with best solution and reasonable price for production line as per customers' invest and capacity requirement

2)Providing turn-key service of site planning, machinery designing, manufacturing, installation and commissioning for the full

production lines to meet customers requirement.

3)Technical support. We will arrange engineers on site to install and debug the production lines until the final products are meet to customers' require

4)Perfect after-sales with long-term technical support, such as after-sales adjust the production line, develop new products or improve the equipment

Packing & Shipping

Product detail pictures:

Related Product Guide:

Cooperation

We've been convinced that with joint efforts, the enterprise between us will bring us mutual benefits. We could guarantee you item excellent and aggressive price tag for High Performance Megatherm Furnace - Steel Scrap Induction Melting Casting Medium Frequency Induction Furnace -Geili, The product will supply to all over the world, such as: Vancouver , Latvia , Colombia , By integrating manufacturing with foreign trade sectors, we can offer total customer solutions by guaranteeing the delivery of right items to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified product portfolios and the control of the industry trend as well as our mature before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!

-

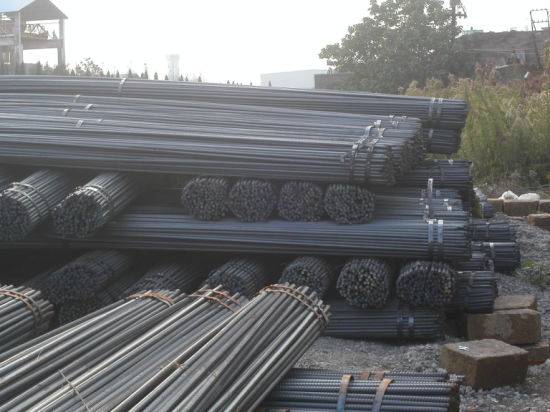

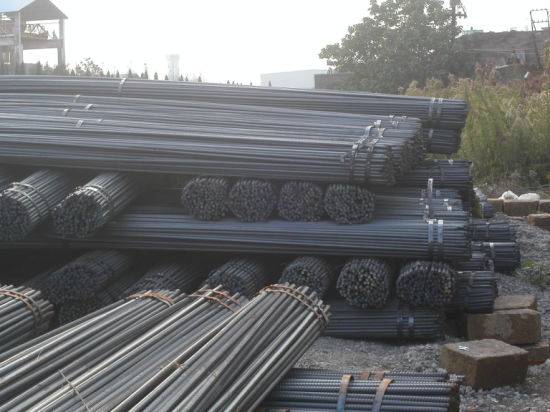

Good Quality Deformend Steel Bar – Precis...

View Detail -

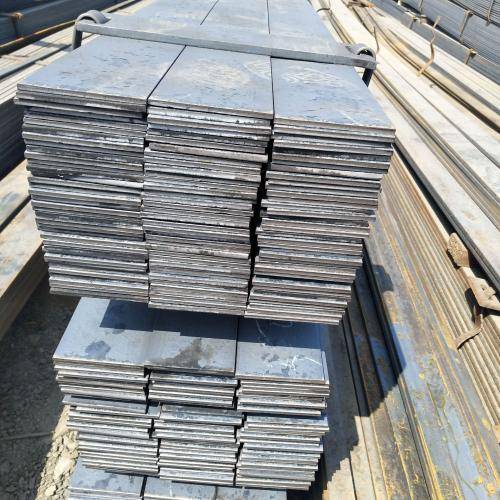

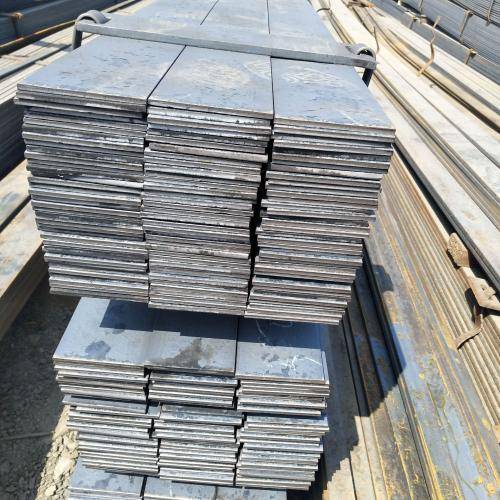

Good Quality Flat Bar – Trade Assurance T...

View Detail -

Good Quality Section Steel – Q253/Ss400 E...

View Detail -

Good Quality Flat Bar – Hot Rolled Mild S...

View Detail -

Good Quality Section Steel – China Manufa...

View Detail -

Good User Reputation for Megatherm Furnace - I...

View Detail