Steelmaking first makes iron. Steel comes from pig iron. Pig iron obtained by smelting iron ore has a high carbon content and contains many impurities (such as silicon, manganese, phosphorus, sulfur, etc.). Therefore, pig iron lacks plasticity and toughness, has poor mechanical properties, and cannot be subjected to pressure processing except for melt casting, thus limiting its use.

In order to overcome these shortcomings of pig iron and make it play a greater role in industry, it is necessary to use oxygen from various sources at high temperature to oxidize and remove impurities in pig iron to a certain extent, so as to obtain certain components and certain Properties of iron-carbon alloys - steel. This method of oxidizing and removing impurities in pig iron at high temperature is called steelmaking.

Fundamentals of Steelmaking

Various impurities in pig iron have a greater affinity with oxygen to varying degrees in a high temperature environment. Therefore, they can be made into liquid, solid or gas oxides by means of oxidation. The liquid and solid oxides react with the furnace lining and the flux added to the furnace at high temperature, combine into slag, and are excluded from the furnace during slag removal. The gas is also carried out of the furnace by CO when the molten steel is boiling.

The entire steelmaking process consists of two processes, oxidation and reduction. Usually, the oxidation of carbon, silicon, manganese, and phosphorus is called the reaction in the oxidation period, and the desulfurization and deoxidation are called the reaction in the reduction period.

Basic Method of Steelmaking

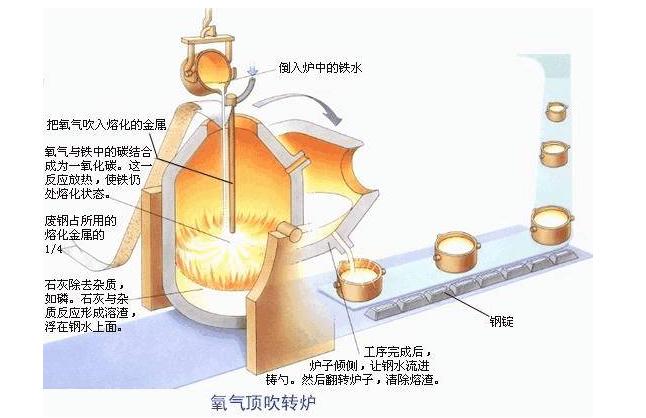

① Converter Steelmaking

The converter steelmaking method is a steelmaking method that uses air or oxygen to oxidize the elements in the molten iron to the specified limit by means of bottom blowing, side blowing and top blowing, so as to obtain qualified steel.

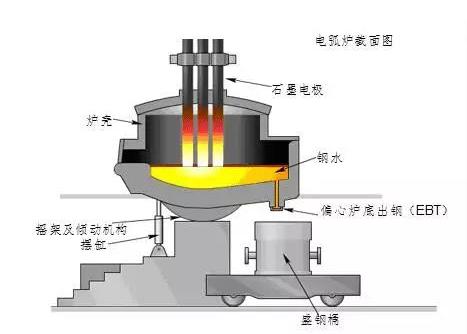

② Electric Furnace Steelmaking

Electric furnaces are used to convert electrical energy into heat energy to make steel. There are two commonly used electric furnaces: electric arc furnaces and induction furnaces. Electric arc furnace is the most widely used, suitable for smelting high-quality steel and alloy steel; induction furnace is used for smelting high-grade alloy steel and non-ferrous alloys.

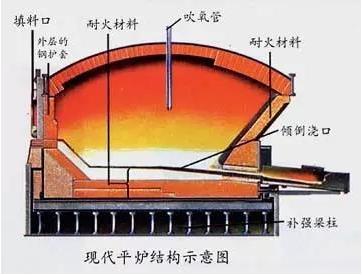

③ Open Hearth Steelmaking

With the development of the industry, a large amount of scrap steel has been accumulated in the metal processing industry. At that time, it was not possible to re-blow it into steel with a converter, so steel workers looked for a steel-making method that used scrap steel as raw material. In 1864, the open-hearth steelmaking method was invented by the Frenchman Martin.

The rapid development of the oxygen top-blowing converter steelmaking method gradually replaced the open hearth steelmaking method. With the advancement of science and technology, some new steelmaking methods continue to emerge, such as vacuum treatment of molten steel, electroslag furnace melting, vacuum induction furnace melting and other methods, which have been used more and more.

Post time: Nov-07-2022